The advent of the Internet of Things (IoT) has revolutionised the way we interact with technology. From smart homes to industrial automation, IoT has permeated almost every aspect of our lives. As the demand for connected devices continues to grow, the need for reliable and efficient cable assemblies has become essential. In this article, we will explore the basics of IoT-ready cable assemblies, the importance of designing them, steps to design them, challenges in the process, and future trends in this rapidly evolving field.

Understanding the Basics of IoT-Ready Cable Assemblies

The Role of IoT in Today’s Technological Landscape

The Internet of Things has transformed the way we live and work. With the ability to connect devices, sensors, and objects to the internet, IoT enables us to gather and analyze data on a scale never seen before. From smart cities to healthcare systems, IoT has the potential to improve efficiency, enhance safety, and create new business opportunities.

Key Components of IoT-Ready Cable Assemblies

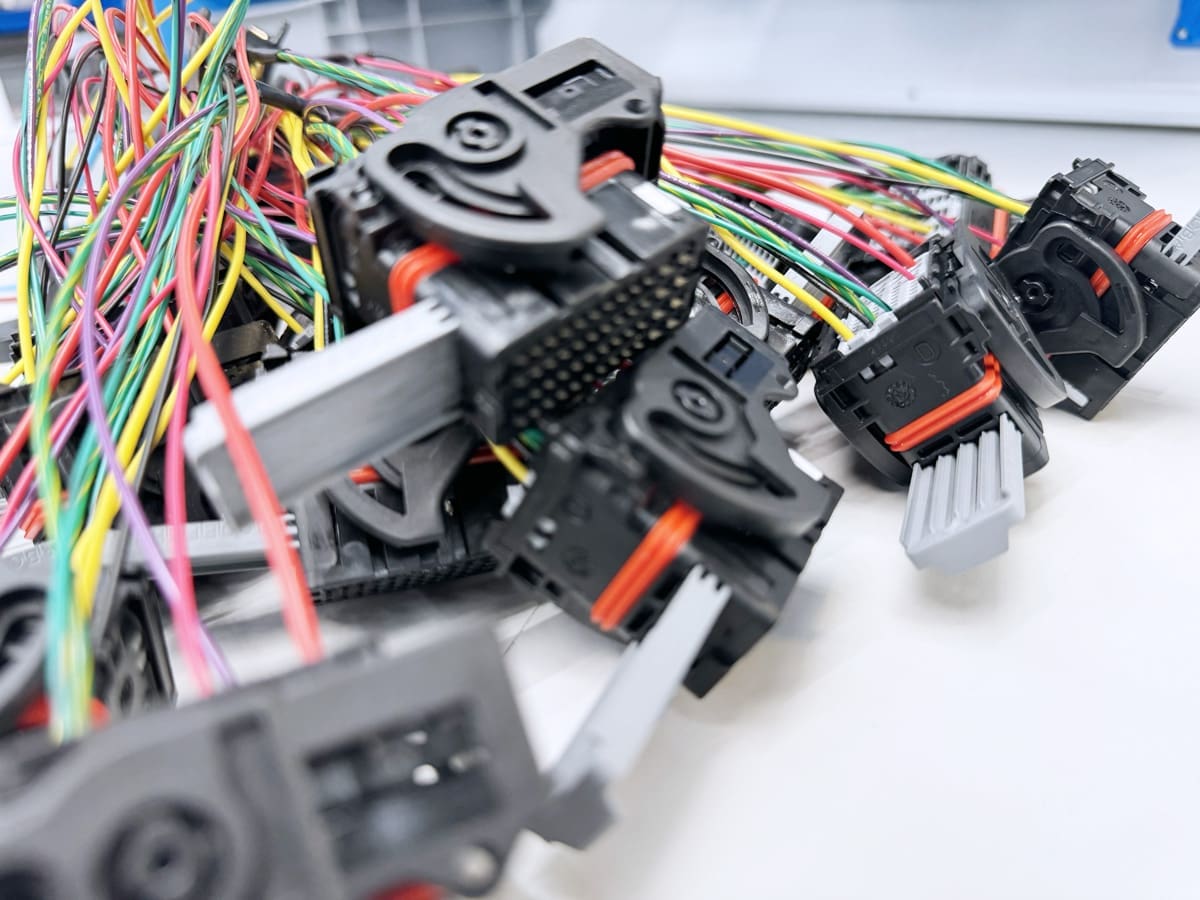

IoT-ready cable assemblies are the backbone of connected devices. They facilitate the transfer of data between sensors, actuators, and central processing units. These cable assemblies consist of various components, including connectors, cables, and shielding. Connectors play a crucial role in ensuring a secure and reliable connection, while cables need to meet specific requirements for data transmission, such as high-speed and low latency.

The Importance of Designing IoT-Ready Cable Assemblies

Meeting the Demand for High-Speed Data Transmission

In today’s interconnected world, high-speed data transmission is essential for IoT devices. Whether it’s a self-driving car or a smart factory, real-time data is critical for making informed decisions and ensuring seamless operations. IoT-ready cable assemblies need to be designed to handle the ever-increasing data volumes and bandwidth requirements.

Ensuring Robustness and Durability in Harsh Environments

Many IoT applications operate in harsh environments, including extreme temperatures, humidity, and vibrations. Cable assemblies need to be designed to withstand these challenging conditions without compromising their performance. Robust connectors, rugged cables, and effective shielding are crucial to ensure long-lasting reliability.

Steps to Design IoT-Ready Cable Assemblies

Identifying the Right Materials and Components

Choosing the right materials and components is the first step in designing IoT-ready cable assemblies. Factors such as durability, signal integrity, and cost need to be carefully considered. Materials like high-quality copper conductors and ruggedized connectors are often preferred to ensure optimal performance and longevity.

Considering the Aspects of Assembly and Installation

The assembly and installation process is as important as the design itself. Attention to detail and adherence to industry standards and best practices are essential to ensure reliable connections and minimize potential issues. Proper strain relief, cable management, and testing procedures play a crucial role in the overall functionality and performance of the cable assemblies.

Challenges in Designing IoT-Ready Cable Assemblies

Dealing with Miniaturization and High-Density Packaging

As IoT devices become smaller and more powerful, cable assemblies need to adapt to the miniaturization trend. Designing and manufacturing cable assemblies with smaller form factors and high-density packaging can be challenging. Precision assembly techniques and advanced manufacturing processes are required to meet these demands.

Overcoming Signal Integrity Issues

Signal integrity is critical for reliable data transmission in IoT devices. Issues such as crosstalk, electromagnetic interference (EMI), and signal loss can lead to data corruption and system failures. Proper cable design, shielding, and impedance control are essential to mitigate these signal integrity issues and ensure accurate data transfer.

Future Trends in IoT-Ready Cable Assembly Design

The Rise of Smart Cable Assemblies

As IoT evolves, so do the requirements for cable assemblies. Smart cable assemblies equipped with built-in sensors, diagnostics, and monitoring capabilities are gaining traction. These intelligent cable assemblies offer real-time data on performance, health, and environmental conditions, enabling proactive maintenance and enhanced system reliability.

The Impact of 5G on Cable Assembly Design

The deployment of 5G networks is set to revolutionize IoT connectivity. With its significantly higher data rates and lower latency, 5G will drive the demand for robust and high-performance cable assemblies. These cable assemblies will need to support the higher frequencies and bandwidths associated with 5G technology, ensuring seamless and reliable connectivity in the IoT ecosystem.

Frequently Asked Questions

1. What is an IoT-ready cable assembly?

An IoT-ready cable assembly is a specialized cable system designed to facilitate the transmission of data between IoT devices. These cable assemblies are built to meet the specific requirements of IoT applications, such as high-speed data transmission, durability in harsh environments, and compatibility with a wide range of connectors and devices.

2. Why is high-speed data transmission crucial for IoT devices?

High-speed data transmission is essential for real-time communication and decision-making in IoT devices. Whether it’s a self-driving car reacting to its surroundings or a smart home adjusting its temperature based on occupancy, seamless and fast data exchange is necessary for efficient IoT operations.

3. What challenges are faced in designing IoT-ready cable assemblies?

Designing IoT-ready cable assemblies comes with challenges such as miniaturization, high-density packaging, and signal integrity issues. Shrinking the size of cable assemblies without compromising performance, managing the complexity of densely packed connections, and ensuring accurate data transmission in the presence of interference are some of the key challenges for designers and manufacturers.

4. How do smart cable assemblies enhance IoT systems?

Smart cable assemblies offer additional functionalities and diagnostic capabilities that improve the performance and reliability of IoT systems. With built-in sensors and monitoring capabilities, these cable assemblies can provide real-time data on performance, health, and environmental conditions, enabling proactive maintenance and efficient troubleshooting.

5. How will the deployment of 5G impact cable assembly design?

5G networks require cable assemblies to support higher frequencies and bandwidths compared to previous generations of wireless technology. This will necessitate the development of cable assemblies that can handle these higher speeds while maintaining signal integrity. The deployment of 5G will also drive the need for cable assemblies that can handle the increasing data volumes in the IoT ecosystem.

In conclusion, designing IoT-ready cable assemblies is essential for enabling the seamless operation of connected devices in the IoT era. By understanding the basics, recognizing the importance, overcoming challenges, and anticipating future trends, designers and manufacturers can meet the evolving demands of this rapidly expanding field. With the right cable assemblies, the potential for innovation and progress in IoT applications is limitless.

As we look towards a future where IoT connectivity is at the heart of innovation, the need for expertly designed cable assemblies is more crucial than ever. Cornelius Electronics, with over four decades of expertise in manufacturing wiring harnesses and cable assemblies, stands at the forefront of this technological revolution. Operating from a state-of-the-art facility in the UK and committed to partnership-focused solutions, they are poised to deliver the high-quality components your IoT projects demand. Get in touch with Cornelius Electronics today to ensure your connected devices are equipped for the challenges of tomorrow.