In recent years, the UK manufacturing sector has witnessed a significant shift towards onshoring, bringing manufacturing processes back to domestic soil from overseas. This movement, driven by a combination of economic, geopolitical, and environmental factors, has started to redefine the landscape of UK manufacturing. Offering a plethora of benefits ranging from enhanced supply chain resilience to substantial economic uplifts. Here, we delve into the multifaceted advantages of onshoring and its impact on the UK’s industrial sector.

Economic and Strategic Benefits

Boost to Local Economy: Onshoring revitalises the UK economy by creating jobs, stimulating local industries, and reducing unemployment rates. It injects capital into local communities, fostering economic growth and stability.

Supply Chain Resilience: The COVID-19 pandemic and subsequent global disruptions underscored the vulnerabilities of extended supply chains. Onshoring mitigates these risks, offering manufacturers more control and visibility over their operations, which in turn enhances supply chain resilience against global shocks.

Quality Control and Brand Reputation: Manufacturing within the UK allows companies to closely monitor production quality and adhere to strict regulatory standards, thereby improving product quality and bolstering brand reputation.

Environmental and Sustainability Gains

Reduced Carbon Footprint: Onshoring helps in lowering the carbon footprint associated with long-distance transportation of goods. By manufacturing closer to the market, companies contribute to global sustainability efforts and align with the UK’s ambitious climate goals.

Promotion of Sustainable Practices: Domestic manufacturing enables firms to implement green technologies and sustainable practices more effectively. It aligns with the growing consumer demand for environmentally responsible products and operations.

Technological Advancements and Innovation

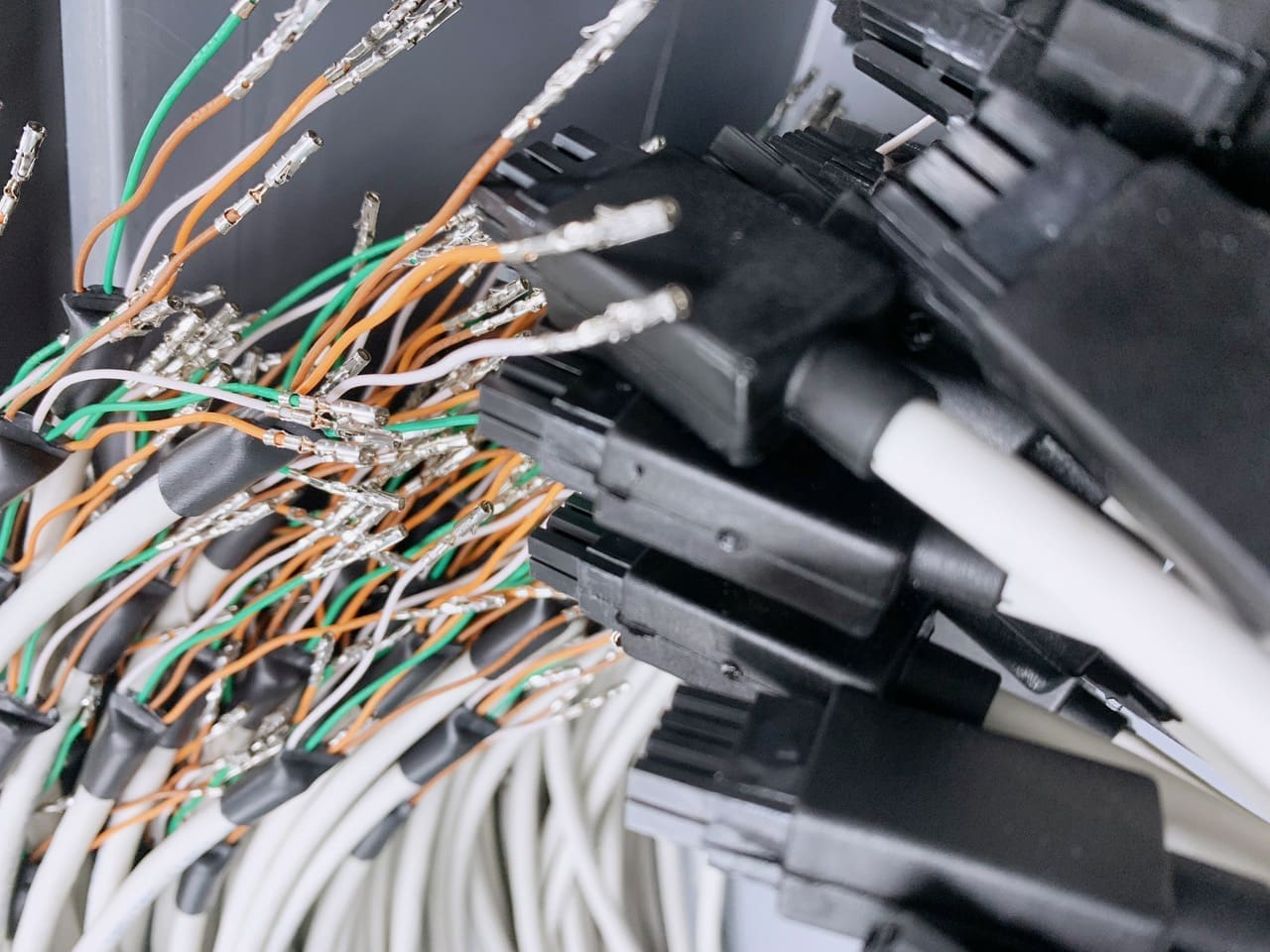

Accelerated Adoption of Advanced Technologies: The UK’s focus on onshoring is accompanied by significant investments in automation, robotics, and digital technologies. This not only enhances operational efficiencies but also positions the UK as a leader in advanced manufacturing techniques.

Innovation Ecosystem: Onshoring stimulates investment and innovation by fostering close collaborations between manufacturers, research institutions, technology providers, and funding institutions. It creates a conducive environment for the development of new products and solutions, further strengthening the UK’s competitive edge in global markets.

Policy Support and Industry Alignment

Government Incentives: The UK government recognises the strategic importance of onshoring and supports it through various incentives, including tax relief schemes, grants, and funding for research and development. These initiatives all assist in ensuring onshoring is a financially viable option for many businesses.

Alignment with Industrial Strategy: Onshoring aligns with the UK’s broader industrial strategy, which aims to increase productivity, economic growth and employment opportunities across the country. It serves as a cornerstone for achieving a balanced and sustainable industrial ecosystem.

Conclusion

Strategically transitioning from offshoring to onshoring with Cornelius Electronics offers powerful and tangible benefits. Including enhanced supply chain control, reduced lead times, and superior product quality. Onshoring simplifies logistics, mitigates risks associated with international supply chains, and aligns with sustainability goals by reducing carbon emissions.

Our expertise in advanced manufacturing, knowledge of global markets, access to powerful supply chains, all coupled with our commitment to innovation and sustainability, means Cornelius Electronics is already delivering on a range of reshoring programs. Forming a true working partnership with us enables access to a robust and agile UK-based manufacturing solution, supporting your business with a faster speed to market service, rapid customisation and a robust, locally supported supply chain.

Connect with Cornelius to reshore for long term mutual resilience and business growth.