A manufacturer’s guide

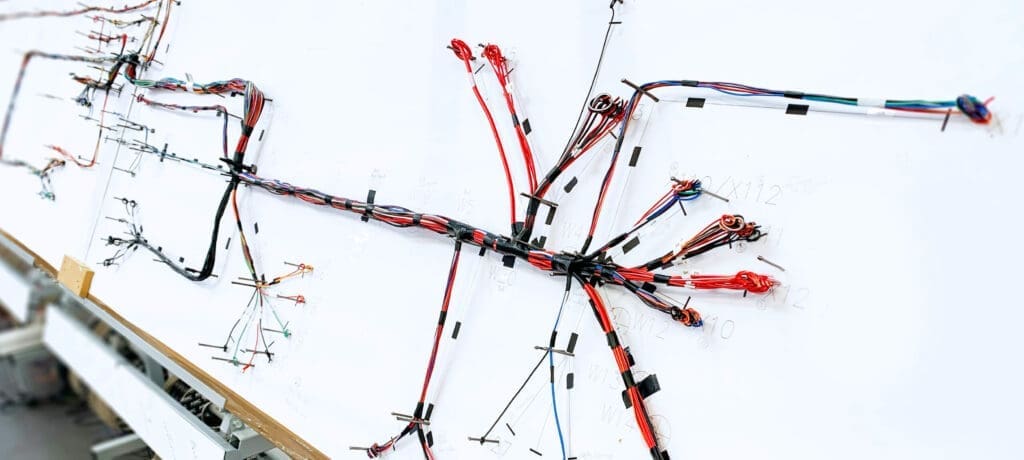

Selecting the right automotive harness suppliers can significantly influence your production quality and operational success. OEMs should focus on key factors when assessing potential suppliers.

This guide outlines the most important criteria for selecting a wire harness OEM manufacturer and the warning signs to avoid.

1. Proven Experience in Automotive OEM Supply

Why it matters:

Automotive wire harnesses are complex and safety-critical. Suppliers with a track record in OEM supply understand the industry’s demanding quality, compliance, and documentation requirements. Collaborating with experienced automotive harness suppliers ensures that your projects meet safety and quality standards.

What to look for:

- Years of experience serving automotive OEMs

- Case studies or references from similar projects

- Recognised certifications such as ISO 9001:2015 (quality management), ISO 14001:2015 (environmental management), UL certification, and IPC/WHMA-A-620 (workmanship standards)

Note: Some OEMs may require IATF 16949 certification; if this is essential for your project, confirm your supplier’s status.

2. Engineering and Customisation Capabilities

Why it matters:

No two vehicle platforms are alike. You need a partner who can collaborate on design, offer prototyping, and adapt to your unique requirements.

What to look for:

- In-house engineering and design teams

- Rapid prototyping and testing services

- Flexibility for custom connectors, lengths, and configurations

3. Scalable, Reliable Manufacturing

Why it matters:

Production delays or inconsistent quality can disrupt your supply chain. Your supplier should have the capacity and systems to deliver high volumes on time, every time.

What to look for:

- Modern, well-equipped facilities

- Automated processes for consistency

- Transparent production schedules and lead times

4. Rigorous Quality Control and Testing

Why it matters:

A single faulty harness can cause costly recalls or safety issues. Robust quality control ensures every harness meets your standards.

What to look for:

- Detailed testing protocols (electrical, mechanical, environmental)

- Traceability for materials and batches

- Commitment to continuous improvement

5. Strong Communication and Support

Why it matters:

Miscommunication can lead to errors, delays, or missed requirements. A responsive supplier keeps you informed and addresses issues proactively.

What to look for:

- Dedicated account managers or technical liaisons

- Clear documentation and regular updates

- Willingness to collaborate and problem-solve

What to avoid

- Lack of relevant certifications or industry experience

- Vague or inconsistent communication

- Unwillingness to provide references or documentation

- No clear process for quality assurance or traceability

Next Steps

Choosing the right automotive wire harness OEM partner is about more than price-it’s about reliability, quality, and long-term value.

By focusing on these factors, you’ll be equipped to select a partner who supports your manufacturing goals and delivers lasting results.