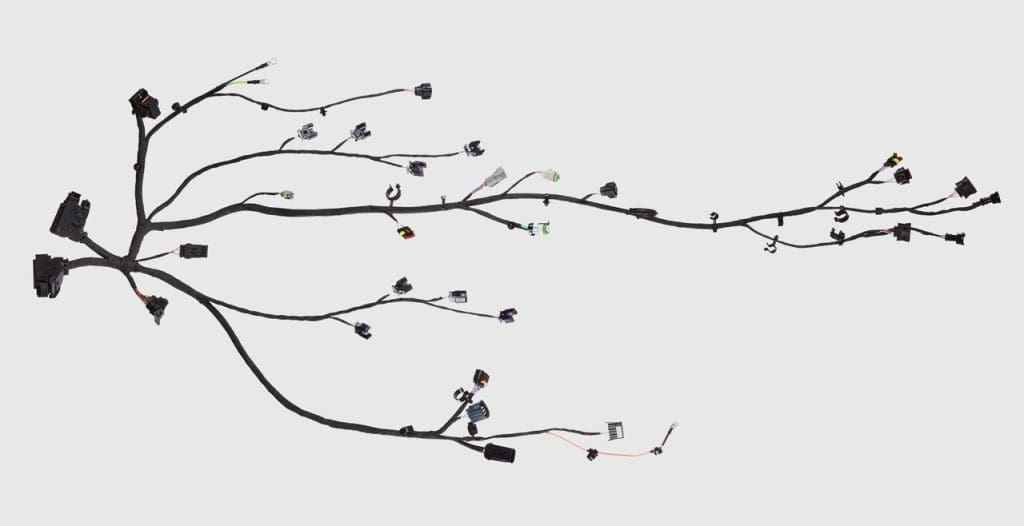

What are Wiring Harnesses?

Wiring harnesses are essential components in modern automation systems, combining multiple wires and cables into a single, organized assembly. This integration ensures efficient signal transmission and power distribution, facilitating reliable and streamlined operations. Wiring harnesses play a crucial role in reducing installation times, enhancing safety, and maintaining system performance.

Why Choose Cornelius Electronics for Wiring Harnesses in Automation?

Cornelius Electronics has been a leader in the manufacturing industry for over 40 years. Based in the UK, our 50,000 square foot facility is equipped with state-of-the-art technology and staffed by over 250 IPC-trained operatives. We specialize in high-mix, medium-volume production, delivering custom wiring harness solutions that meet the exacting standards of automation systems.

Benefits of Wiring Harnesses for Automation

- Improved Efficiency:

Wiring harnesses simplify the assembly process by consolidating multiple wires into a single unit. This reduces installation time and ensures that your automation systems are up and running quickly and efficiently. - Enhanced Safety:

By organizing wires into a single harness, potential hazards such as electrical shorts and loose connections are minimized. This enhances the overall safety and reliability of your automation systems. - Space Optimization:

Wiring harnesses help to optimize space within your equipment by neatly bundling wires together. This is particularly important in automation systems where space is often at a premium. - Ease of Maintenance:

With wiring harnesses, maintenance becomes simpler and more straightforward. Identifying and addressing issues is easier, reducing downtime and keeping your automation systems operating smoothly. - Customization:

At Cornelius Electronics, we offer customized wiring harness solutions tailored to the specific needs of your automation systems. Whether you require specific lengths, connectors, or configurations, we can deliver a product that meets your exact specifications. - Durability:

Our wiring harnesses are built to withstand the rigors of industrial environments. We use high-quality materials and advanced manufacturing techniques to ensure long-lasting performance and reliability.

Our Wiring Harness Services for Automation

Cornelius Electronics offers a comprehensive range of wiring harness services designed to meet the unique requirements of automation systems. Our capabilities include:

- Design and Engineering Support: Our experienced engineers work closely with you to design wiring harnesses that maximize efficiency and performance.

- Material Selection: We help you choose the right materials for your wiring harnesses, ensuring optimal durability and functionality.

- Prototyping and Testing: We provide rapid prototyping services to test and refine designs before full-scale production.

- Production: Our facility is equipped for high-mix, medium-volume production, ensuring consistent quality across all units.

- Quality Assurance: Rigorous testing and inspection processes ensure that every wiring harness meets the highest standards of performance and reliability.

Industries We Serve

Cornelius Electronics provides wiring harness solutions for a wide range of industries that rely on automation, including:

- Manufacturing: Enhancing the efficiency and reliability of automated production lines.

- Automotive: Supporting advanced vehicle automation and electronic systems.

- Aerospace: Ensuring the performance and safety of automated aerospace applications.

- Medical Devices: Providing reliable wiring solutions for automated medical equipment.

- Industrial Equipment: Improving the functionality and durability of automated industrial machinery.

Why Partner with Cornelius Electronics?

- Experience and Expertise: With 40 years in the industry, we have the knowledge and skills to deliver superior wiring harness solutions for automation.

- State-of-the-Art Facility: Our 50,000 square foot production facility is equipped with the latest technology and staffed by over 250 IPC-trained operatives.

- True Partnerships: At Cornelius Electronics, we believe in building true partnerships with our clients. We work closely with you to understand your needs and deliver solutions that exceed your expectations.

- High-Mix, Medium-Volume Production: We specialize in high-mix, medium-volume production, providing flexibility and efficiency for diverse project requirements.